Vertical Machining Centers (VMC), also called Vertical Milling Machines, play an essential role in modern manufacturing. The use of these machines has changed the whole concept of creating precise parts and components. VMCs are widely used in sectors like automotive, aerospace, and medical devices.

Knowing the basics of these machines will help you understand their importance in today’s manufacturing industry. VMC Job work includes creating high-quality machine components and bringing efficiency to production.

Table of Contents

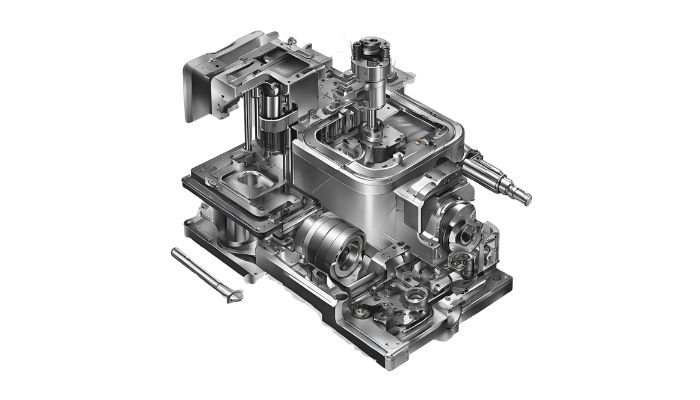

Basic Components And Working Principles

- Axes of Motion (X, Y, Z)

VMC machine manufacturer in India move in three main directions: left and right (X-axis), up and down (Y-axis), and forward and backward (Z-axis). These movements let the machine position the cutting tool accurately and perform detailed machining tasks with precision.

- Worktable and Fixturing

In VMC machines, the worktable is a platform where you place the item during machining. You can move it left and right (X-axis) and forward and backward (Y-axis) to position the item correctly under the cutting tool. To keep the item steady while machining, you can use different tools like clamps, vises, and fixtures.

- Vertical Spindle

The vertical spindle is the main part of every VMC (Vertical Machining Center) machine. It holds the cutting tool and spins quickly to cut material from the workpiece. The spindle’s vertical position helps remove chips effectively and improves the smoothness of the surface during vertical milling tasks.

- Tool Changer Mechanism

Many VMC machines have an automatic tool changer (ATC) that makes it easy to switch between different tools during machining. This helps operators change tools quickly, which cuts down on waiting time and boosts productivity.

- Control System (CNC)

VMC machines use a computer system to control how they move and work. This system reads instructions from a program, converts them into precise movements, and performs the machining tasks accurately and consistently.

Advantages Of VMC Machines

VMC machines have many advantages, making them popular among many industries. The demand for VMC machine manufacturing is becoming popular and generating jobs since experts are needed to operate these machines. People now are exploring the internet and searching for “VMC Job work near me” and “VMC Job work in Delhi NCR”. Other than providing jobs, the benefits of VMC machines include:

- High Precision Machining

VMC machine in India are the top choice for making components and parts of machines because they are really good at making these components very accurately and consistently. Thus industries like aerospace, automotive, and medical manufacturing opt for VMC machine service providers since the quality of manufacturing is very important in these industries.

- Efficient Production Processes

The production process with the use of VMC machines becomes very efficient. These machines have advanced features like automatic tool changers, fast spindles, and the ability to work in multiple directions. These features help them work faster and more efficiently, saving time, boosting productivity, and lowering the cost of making each part. It is a great way to create machine components compared to doing the same work manually.

- Cost-effectiveness

Even though VMC machines need a good investment at first, they save money for a long time. They boost productivity, cut down on waste, and lower labor costs. These machines can easily make complex components in a single step, reducing the need for extra operations, which helps cut overall manufacturing costs.

- Versatility in Material Compatibility

VMC machines are known for versatility and can work with many different materials like plastics, metals, and composites. This makes them useful for completing various manufacturing tasks in different industries, from making aluminum parts to working with tough steel.

- Automation and Integration Capabilities

Many VMC (Vertical Machining Center) machines can work with robotic loaders and automation systems. This feature of VMC machines reduces the need for any person to be there. They can also connect with CAD/CAM software, making it easier to program and run the machines efficiently.

Global Precision – The Best VMC Machine Service Provider

Global Precision is a leading VMC India machine service provider in India. The goal of the company is to provide an unmatched level of VMC machining services to its clients. With the high-tech precision of VMC machined parts, the main goal of the company is to keep clients happy.

Using the VMC machine, Global Precision makes various machine parts, like pump covers and other metallic body parts of machines. The company ensures perfection and accuracy by using different methods to complete the work.

Why Choose Global Precision?

If you are looking for the best VMC machine service provider for your manufacturing tasks, opting for Global Precision can be very beneficial for your manufacturing operations. The manufacturing company provides a wide range of precision machining services, making it a great choice for Industries that demand high-quality manufacturing of machine components.

At Global Precision, there are the best VMC machines along with the top job VMC operator to complete precision tasks to ensure the quality of production.