The smallest, invisible details frequently have the greatest impact in the fields of fluid dynamics and industrial control. From your home plumbing to large petrochemical plants, the valves that control the flow of water, oil, gas, and chemicals in vital infrastructure must always function perfectly. The manufacturing process and the materials are the foundation of this dependability.

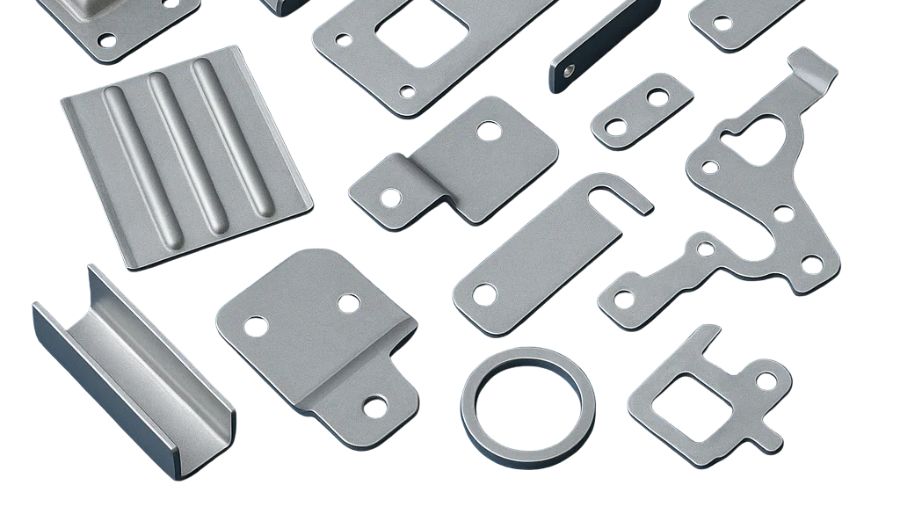

High-precision aluminum components fill this need by providing a potent blend of robust performance and lightweight efficiency that is revolutionizing valve manufacturing components. At the forefront are businesses such as Global Precision Pvt. Ltd., which uses cutting-edge technology to transform aluminum into high-tolerance, mission-critical components.

Table of Contents

The Aluminum Advantage – Why Choose This Light Metal For Valves?

When engineers design a valve, they have a number of material choices, including brass, steel, and plastics. However, aluminum alloys have become a preferred option for so many applications, particularly where performance should be balanced with cost and weight.

1. Exceptional Strength-to-Weight Ratio – Aluminum is about one-third the weight of steel. This low density means the final valve assembly is lighter, which is vital for applications such as automotive, aerospace, and portable tools, decreasing load and enhancing energy effectiveness.

2. Natural Corrosion Resistance – When exposed to air, aluminum forms a thin, strong layer of aluminum oxide on its surface. This layer works as a natural, extremely useful protection against rust and several corrosive environments, a property that can be further improved with treatments such as anodizing.

3. Outstanding Machinability – Aluminum is relatively smooth, which means it can be cut, shaped, and drilled quickly and more effortlessly than tougher metals such as stainless steel. This permits manufacturers to gain complicated shapes and super-tight tolerances without driving up production time and expenses.

4. Excellent Thermal Conductivity – Aluminum effectively turns heat away, which can be a major aspect in valves running in high-temperature environments or handling cryogenic fluids, assisting in sustaining stable performance.

The Role Of CNC Aluminum Machining in Achieving Perfection

The remarkable advantages of aluminum are only really unlocked through ultra-precise manufacturing strategies. Computer Numerical Control is the technology that takes an easy block of aluminum and transforms it into a complicated, ideally formed valve part.

What is CNC Machining?

CNC stands for Computer Numerical Controls, which means a computer program accurately controls the movement of cutting tools to carve out the final part from a raw piece of material.

Why is CNC Critical For Valve Parts?

Industrial valves are complicated mechanical systems where every part, from the body and bonnet to the stem, disc, and seats, should fit together with near-perfect precision. A single micron of mistake can cause leakage, poor flow control, and catastrophic system failure.

1. Unmatched Precision and Tight Tolerances – CNC machines can constantly gain tolerances as small as some thousandths of an inch. These precision aluminum components make sure that sealing surfaces are ideally flat and seamless, resulting in a leak-tight valve.

2. Repeatability – Once the CNC program is ideal, the machine can produce thousands of identical aluminum CNC parts. This consistency is crucial for mass production, making sure every valve that rolls off the assembly line fulfills the precise same high standard.

3. Complex Geometries – Valves usually need complicated internal channels, threaded ports, and complicated curves to handle fluid flow. Multi-axis CNC machines can make these highly complicated features in a single setup, which is impossible with older, manual techniques. This is specifically crucial for producing modern valve manufacturing components.

Partnering with the Experts – Global Precision Pvt Ltd

For manufacturers across sectors such as oil & gas, pharmaceuticals, food and beverage, and automotive, selecting the appropriate partner to supply precision aluminum components is a vital business decision.

Global Precision Pvt Ltd stands out as a leader in giving top-quality aluminum CNC parts for demanding applications. This procedure merges three vital pillars –

1. Cutting-edge Technology – They use the current multi-axis CNC machines, making sure they have the capability to produce the most complicated and high-tolerance designs needed by advanced valve systems.

2. Material Expertise – They work with different aluminum alloys, from the typical-purpose 6061 to the high-strength aerospace-grade 7075, to match the material’s properties accurately to the functioning environment of the valve.

3. Rigorous Quality Control – Every element goes through strict quality checks utilizing modern measurement equipment to assure that the final part is precisely to specification, sustaining the integrity of the finished valve.

By paying attention to these principles, Global Precision Pvt Ltd assists valve manufacturers in improving their product performance, decreasing assembly time, and remarkably extending the service life of their valves, delivering an affordable solution for long-term trustworthiness.

The Future is Precise – Aluminum in Next-Generation Valves

As sectors constantly push the boundaries of performance and effectiveness, the need for high-precision, trusted valve manufacturing components will only grow.

Aluminum parts, manufactured with the accuracy of CNC aluminum machining, are ideally positioned to fulfill this future. They enable the creation of smarter, lighter, and more complicated valves that can manage higher pressures, more corrosive fluids, and quicker cycle times than ever before. From specialized management valves in robotics to high-volume automotive components, the mix of aluminum’s beneficial properties and the unerring precision of contemporary CNC technology is a game-changer.

If your business depends on flow control, making sure your valves are formed with high-precision aluminum components from a reliable partner isn’t only about quality; it is about assuring protection, effectiveness, and long-term functional success.