In the high-speed industrial environment, precision and dependability are essential, especially in Metal Component Manufacturing. CNC machining has become a leading technology that provides unbeatable accuracy, repeatability, and speed. Even if it is in the aerospace, automotive, or medical industry, manufacturers are turning to CNC machines more and more to manufacture intricate metal parts to stringent specifications. CNC machining reduces human error and provides consistent quality over extended production runs, unlike traditional processes.

With the rising demand for performance-oriented, durable components, CNC machining is the most effective and scalable approach. Through this comprehensive blog, let’s understand in detail how CNC machining is ideal for metal component manufacturing.

Overview Of CNC Machining:

CNC is an acronym that stands for Computer Numerical Control. CNC is the use of computerized software to determine how a machine moves and operates. It works by taking a digital model of a part and converting it into a series of computer instructions that tell the machining tools what to do to create the part you want.

CNC equipment may work on a wide variety of parts, including metals, metal alloys, wood, stone, etc., and the size of the machining tools can vary, depending on what part needs to be created. Since CNC is controlled by a computer system, CNC operations can provide much more significant levels of versatility, efficiency, and precision compared to other common manufacturing methods. This is why CNC is a preferred manufacturing choice in many industries and applications.

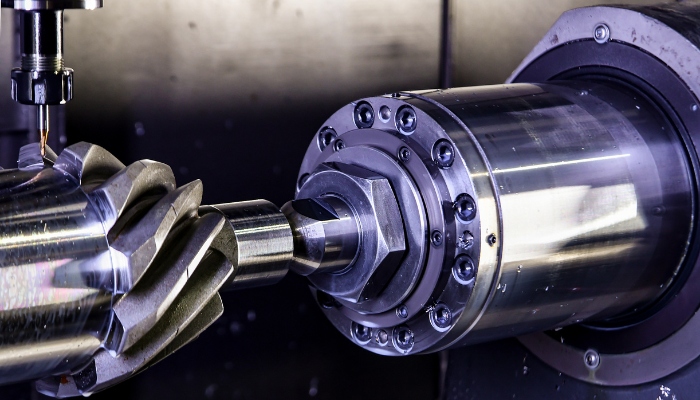

How CNC Machining For Metal Component Manufacturing Works:

Metal CNC machining is an accurate and fast method of fabrication in metal component manufacturing. It consists of the following key stages that convert a digital design into a finished and high-quality metal component:

- Designing: Using CAD (computer-aided design) software, engineers create a 3-D model of the component, which shows the specifications and dimensions needed for the manufacturing process.

- CAM Programming: The CAD file is processed through CAM (computer-aided manufacturing) software, which creates a program for the CNC machine (G-code) that describes how the part will be manufactured.

- Setup: The CNC machine is set up by trained operators with the correct cutting tools selected and the raw metal material mounted to the machine.

- CNC machining: The CNC machine then operates under the G-code instructions to cut and shape the material to the correct dimensions and specifications of the design to produce the finished component.

- Finishing: Once the CNC machining is complete, the finished component can undergo further finishing operations such as deburring, polishing, or coating, to change its appearance and improve its performance.

A component manufacturing company uses this process to produce complex and durable parts and components for different industry applications with consistency, precision, and repeatability for every metal component produced.

Key Advantages Of CNC Machining For Metal Component Manufacturing?

CNC (Computer Numerical Control) machining has evolved into a vital process in metal component manufacturing as it enables precision, speed, and flexibility beyond traditional fabrication processes. The five major benefits illustrate why CNC technology is preferred by today’s manufacturing companies:

1. Producing Complex Designs

VMCs (vertical machining centers) are capable of producing intricate and very detailed parts of many directly manufactured shapes that would be too complicated or too expensive to manufacture manually. This allows manufacturers to innovate and manufacture complex metal parts for sophisticated applications.

2. Superior Accuracy

One of the greatest features of CNC machining is its precision. This consistency means that any part produced is guaranteed to be the same every time. This level of accuracy is necessary in industries like aerospace and medicine, where if there is the slightest error in a metal component, it may cause destructive failure.

3. High-Speed Manufacturing

CNC machines also operate continuously once they are programmed, which also cuts down on production cycles. Rapid production is important for component manufacturing companies that need to produce components in a short amount of time without sacrificing consistency and quality.

4. Efficiency and Material Optimization

In CNC machining, less material is wasted when using an optimized cutting path and instructions, which allows for efficiency in the manufacturing process and lower manufacturing costs. Further, with lower waste, there are better opportunities for sustainable practices in your manufacturing of metal components.

5. Material Versatility

CNC machines work rarely with metals that come from aluminum and brass to strong alloys such as titanium and stainless steel. CNC machining can serve a range of industries and companies, from automotive to defense or electronics, to even a component manufacturing company.

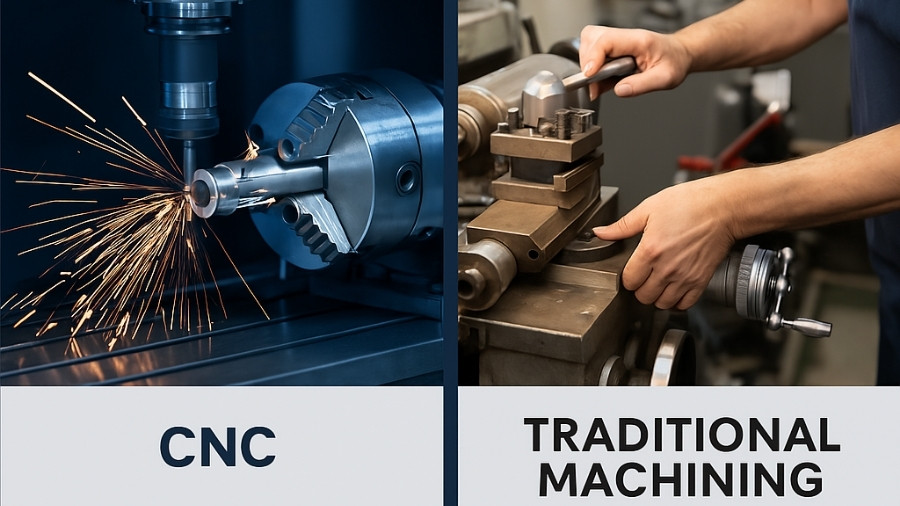

CNC Machining vs. Traditional Machining in Metal Component Manufacturing

CNC machining comes with a range of advantages as compared to typical manual manufacturing methods for metal component production. Here is an overview:

- Precision: CNC machines provide accurate and repeatable results that are well-suited for delivering highly complex parts made from metal with tight tolerances.

- Speed: Once programmed, a CNC-programmed system can produce parts quickly, especially if it is producing lots of complex geometries that were easier to produce this way than by manual methods.

- Flexibility: CNC machines for Metal Component Manufacturing allow for very quick setup changes, which is great for customizing components quickly and for producing components in small batches with little downtime.

- Cost: CNC machining has a bigger up-front cost due to higher setup and programming time, but is economically less costly over time. Compared to traditional methods, it does not allow for repeating projects or for low-volume production of complex parts.

- Material Waste: CNC programming is usually more efficient by nature in terms of material. Advanced software allows for really good planning and cutting paths, which reduces scrap. This is key for any component manufacturing company trying to simplify their poor manufacturing and reduce waste and costs.

How To Choose a Metal CNC Machining Provider?

Here is how you can find a reliable provider of metal component manufacturing in India:

1. Equipment and Technologies

Make sure your provider has not only modern CNC machines but also complex Metal Component technologies that are capable of handling complex fabrication with consistent accuracy.

2. Experience and Expertise

Select a Component Manufacturing Company that has experienced engineers who have worked on a variety of projects. This means successful past projects with engineers who have a full grasp of the components and can provide the best understanding of the full range of component attributes.

3. Quality Control Measures

Make sure that you verify that they have a process for evaluating quality, which should be complete and rigorous. Quality checks should be done on every part to check if it meets the required specifications of standard Metal Component Manufacturing processes.

4. Certifications and Standards

It’s a good idea to check whether the company has any certifications. As quality and reliability are paramount in Metal Component Manufacturing, you must understand how the company is committed to meeting those requirements.

5. Delivery and Flexibility

There are many component manufacturing companies that are able to deliver quickly, but not all of those are going to maintain flexibility in meeting short lead time demands.

6. Customer Service and Communication

As a client, you should expect a level of responsiveness where your provider will keep you informed of the project’s progress so you and others are not surprised by delays on the project.

Conclusion

CNC machining is changing the world of Metal Component Manufacturing with superior precision, speed, and ability to reproduce complex designs with repeatability. Industries across the spectrum, from aerospace to automotive, depend on CNC technology to manufacture components to stringent standards. CNC Machining provides efficiencies, material utilization, and custom production options, which further make it suitable for even the large and small batch production of components.

For those looking for a trusted component manufacturing company, choose Global Precision Pvt Ltd, India’s premier CNC machining service provider, that produces high-quality precision-engineered components. We make the most of our latest technology to produce high-volume products and deliver components on time. Therefore, reach out to us for precision metal component manufacturing.