In a world operating on electricity, from the smallest microchip to the biggest power grid, there is one material that stays utterly indispensable – copper. It is the original conductor, the metal that has smoothly transitioned from old-school wiring to the high-tech parts of the 21st century. Particularly, copper sheet metal parts are the spine of contemporary electrical engineering.

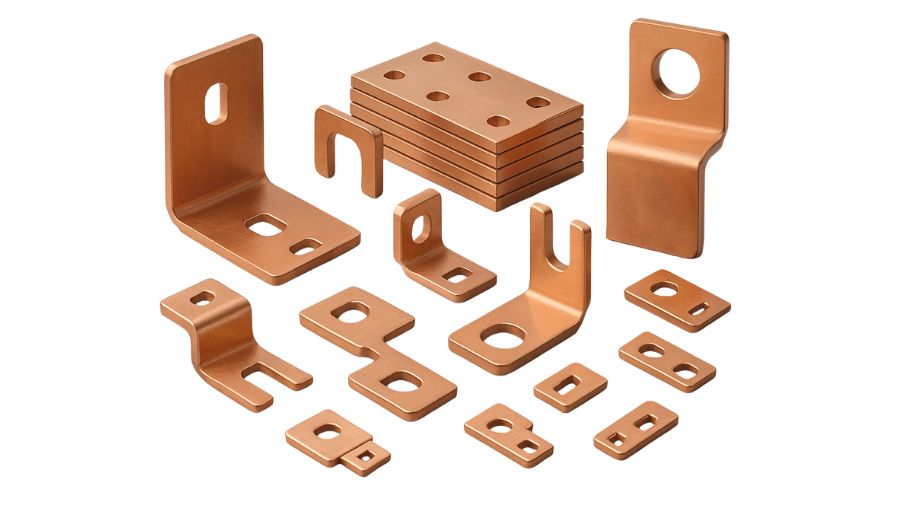

These thin, accurately structured pieces of copper are utilized everywhere to make sure electricity flows safely, effectively, and reliably. For industry leaders such as Global Precision Pvt Ltd, professionally fabricating these parts isn’t only a job; it is a dedication to powering the future.

Table of Contents

The Copper Advantage – Why Conductivity is King

When developing an electrical system, the major objective is to move energy from Point A to Point B with the least amount of resistance. This is where copper shines. Its properties ideally supported the demanding needs of the electrical world.

1. Unmatched Electrical Conductivity

Silver is the only metal with higher electrical conductivity than copper, but silver’s charge makes it impractical for mass-market usage. Copper is the most conductive, affordable, and readily available metal conductor –

- Low Resistance – Copper delivers minimal resistance to the flow of electric current. This is vital because low resistance means less energy is lost as heat. In large-scale power transmission and high-current applications, this translates directly to huge cost savings and enhanced system effectiveness.

- Safety and Efficiency – Less heat production means the parts can manage higher current loads without overheating, which is the main aspect in controlling tool failures and electrical fires.

2. Exceptional Thermal Conductivity

Electricity always produces some heat. When current flows through a conductor, it requires a way to dissipate that heat rapidly and effectively. Copper is an outstanding thermal conductor, meaning it can dissipate heat away from sensitive electronic spaces.

- This dual conductivity, both thermal and electrical, makes it perfect for elements such as heat sinks and cooling systems, which are vital for securing microprocessors, power supplies, and batteries in electric vehicles.

3. Durability and Corrosion Resistance

Electrical parts usually function in harsh environments, from damp industrial plants to outside utility boxes.

- Longevity – Copper naturally forms a stable, secure layer when exposed to air and moisture. This oxide layer protects the underlying metal from rust and corrosion, providing copper components for electrical industry with an excellent lifespan in comparison to several other materials.

- Ductility and Malleability – Copper is extremely ductile and malleable. This adaptability permits it to be structured into complicated and intricate structures needed for advanced connectors and terminals without losing its strength.

From Sheet To Spark – The Power Of Sheet Metal Manufacturing

The copper utilized in several electrical applications does not begin as a strong bar; it begins as a thin, flat sheet. Sheet metal manufacturing is the procedure that turns these raw materials into extremely accurate operational elements.

What is Copper Sheet Metal Fabrication?

Sheet metal manufacturing includes taking a flat coil or sheet of copper and utilizing specialized equipment and machinery to cut, bend, punch, and structure it into a final three-dimensional part. For electrical parts, this procedure should be extremely precise to make sure an ideal fit and a trusted electrical contact.

Essential Copper Sheet Metal Parts in the Electrical World

The effect of top-quality copper sheet metal parts can be seen throughout the electrical ecosystem. These are a few of the most typical and crucial applications –

1. Busbars and Power Distribution

Busbars are crucially big strips of copper sheet metal that distribute electric power within switchgear, panel boards, and battery banks. They allocate power from a prime source to smaller circuits.

- Why Copper Sheet Metal? The flat, wide structure enhances surface space for current flow and heat dissipation. Their custom structures are gained through cutting and punching copper sheet, which is more affordable and delivers better thermal performance than just utilizing thick round wire.

2. Connectors and Terminals

These are the points where wires or elements are physically joined. Everything from a straightforward household plug to a high-current industrial breaker depends on them.

- Why Copper Sheet Metal? Terminals and connectors should be extremely conductive and sustain spring tension or pressure for a trustworthy, tight fit. Copper sheet is bent and formed to make clips, crimp terminals, and internal contacts as circuit breakers, making sure a strong connection that reduces energy loss.

3. Transformer and Coil Components

Transformers are gadgets that change voltage levels. They are vital for both stepping up power for long-distance transmission and stepping down power for secure household usage.

- Why copper sheet metal? These copper components for electrical industry are utilized for windings and internal connectors, enhancing effectiveness and heat transfer within the densely packed core of the transformer.

4. Grounding and Earthing Systems

These elements deliver a secure path for electrical current to disperse into the earth, controlling shocks and securing tools from surges.

- Why copper sheet metal? Copper’s conductivity and corrosion resistance make it the perfect material for grounding straps, plates, and lugs, making sure the protection system remains useful for decades, even when buried underground or exposed to weather.

The Precision Partner – Working with Global Precision Pvt Ltd

When dealing with electricity, there is no room for mistakes. The performance of your final product, be it a huge power generation system or a small consumer electronic gadget, is directly tied to the quality of its copper sheet metal parts.

This is why connecting with a professional in sheet metal manufacturing and CNC copper fabrication is crucial.

Global Precision Pvt Ltd has expertise in providing elements that fulfill the precise, non-negotiable norms of the electrical industry. They comprehend that –

1. Tolerance is Power – They employ modern multi-axis CNC machinery and accuracy measuring equipment to make sure every bend, hole, and cut is manufactured to ultra-tight tolerances. This assures excellent contact and minimal resistance in the final assembly.

2. Material Matters – They source and work exclusively with certified, high-purity copper alloys to make sure maximum electrical and thermal performance, which is a non-negotiable need for crucial copper components for electrical industry.

3. Finishing Enhances Performance – For demanding applications, copper is usually finished with treatments such as tin or silver plating. Global Precision Pvt Ltd delivers these services to further improve conductivity, enhance solderability, and control oxidation over the long service life of the component.

By paying attention to accuracy at each phase, from the raw copper sheet metal parts to the final plated product, Global Precision Pvt Ltd delivers manufacturers with the trusted foundation required to structure high-performance electrical systems.

Sustainability And The Future Of Copper

The part of copper in the electrical industry is only developing, driven by two prime international changes –

1. Renewable Energy – Solar, wind, and battery storage systems need huge amounts of extremely conductive materials to handle and transfer power effectively. Every solar panel and battery pack requires accurate copper elements.

2. Electric Vehicles – EVs are crucially big, complicated electrical systems. Their performance is described by high-current connectors, busbars, and battery terminals, almost all of which are made from copper sheet metal to handle the high power and heat.

Copper is also a champion of stability. It is 100% recyclable without any loss of quality. This means the copper elements of today can be melted down and reformed into the next era of elements, supporting a truly circular economy, a huge environmental and economic advantage.

The future of energy is high-current, low-resistance, and extremely effective. The accurate fabrication of copper components for the electrical industry isn’t only supporting this future; it is making it possible. Through modern methods such as CNC copper fabrication, the humble copper sheet metal part will continue to be the strong, trusted core of all our electrical systems.