Industrial valves are essential to every significant industry, including petrochemicals, power generation, pharmaceutical manufacturing, and even advanced water treatment. The “traffic cops” of fluid systems, these crucial control points are in charge of precisely regulating the flow, pressure, and direction of liquids, gases, and slurries. A valve failure can have disastrous results, including millions of dollars in lost output, significant environmental harm, and dangerous safety risks.

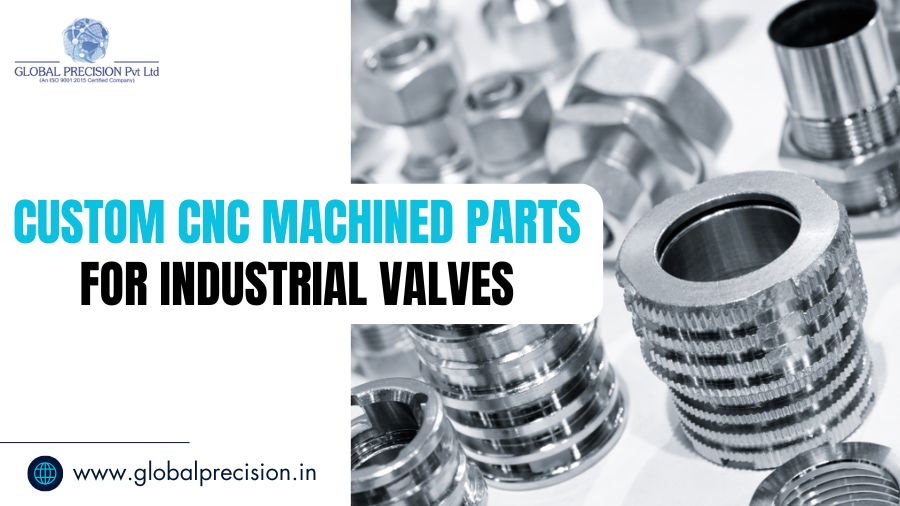

The accuracy and quality of an industrial valve system’s internal components directly affect its performance, longevity, and safety. The dependability needed in these harsh, high-stakes environments is simply not achievable with standard, mass-produced parts. This is why the demand for custom CNC machined parts for industrial valves has grown significantly. Custom CNC machining enables the production of highly specific, tailor-made components designed to meet exacting operational needs. These parts are manufactured from premium materials, carefully chosen for their ability to withstand extreme conditions, including high temperatures, pressures, and exposure to corrosive substances.

For operational safety and success, selecting the best CNC manufacturing services provider is therefore a requirement rather than a choice.

Table of Contents

Why “Custom” is Critical – Beyond Off-the-Shelf Solutions

“Close enough” invites failure in the context of fluid control. Custom CNC parts are a must because industrial valve components operate in some of the harshest environments on the planet –

A. Managing Severe Operating Conditions

Valves are subjected to extreme stresses during industrial processes that are too great for standard parts to withstand –

- High Temperature and Pressure – Parts must endure extreme internal forces and thermal cycling without warping, which would cause leaks right away.

- Corrosion and Erosion – Parts are exposed to extremely corrosive media in chemical or oil and gas applications. They have to be made from particular exotic alloys that are chosen for their chemical resistance, such as Inconel, Monel, or specialty stainless steels.

- Abrasive Materials – To withstand rapid wear and tear, valves handling slurries, sand, or other particulate matter need components with extremely hard surfaces.

The accurate application of these material specifications is ensured by CNC machining for valves. Because of its custom nature, engineers can select an alloy that precisely mitigates the risks associated with a given application, extending the life of industrial valve components.

B. The Imperative of Tight Tolerance and Perfect Sealing

When a valve is closed, its main purpose is to provide a perfect seal. In order to achieve this, the sealing surfaces must be machined with almost no dimensional error.

- Tolerance Levels – Single-digit micron tolerances, which are much thinner than a human hair, are frequently needed for precision machined valve parts. This accuracy can be attained by CNC machines, but not by manual or less sophisticated means.

- Perfect Surface Finish – To guarantee a full, leak-proof seal and to lessen friction on moving components like valve stems, the surface finish must also be flawless. Only specialized CNC manufacturing services can achieve this level of finish.

The Power of CNC Machined Parts – From Digital Blueprint to Flawless Component

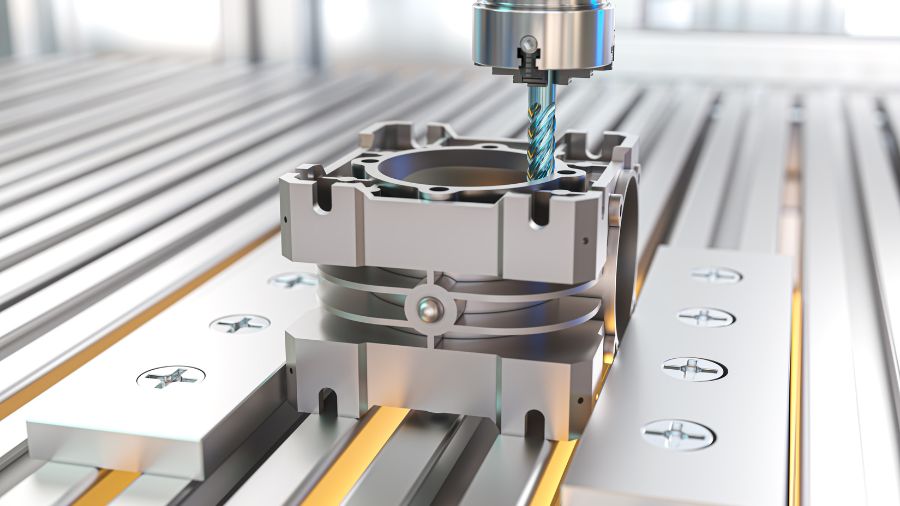

Computer software pre-programs the movements of machine tools such as lathes, mills, and grinders in a manufacturing process known as computer numerical control, or CNC machining. The manufacturing of high-performance industrial valve components is made possible by this technological advancement.

A. Superior Precision and Reliability

Human variability, the leading cause of defects, is eliminated when digital programming replaces manual control.

- Digital Accuracy – A 3D CAD model is used to start the process. Every movement, cut, and speed is controlled by the machine’s language, G-code, which is translated from this digital blueprint. Cycle after cycle, the machine runs this program flawlessly.

- Consistency is Safety – For critical infrastructure, the capacity of CNC machines to create thousands of identical custom CNC parts is an absolute necessity. Every valve in a system will have precisely the same performance characteristics thanks to this repeatability, which is crucial for quality control and safety certification.

B. Multi-Axis Capability for Complex Geometry

Multi-axis (3-, 4-, and 5-axis) machines are used in contemporary CNC manufacturing services to produce the intricate, complex shapes that are present inside high-performance valves.

- Efficiency of Single Setup – A complex part can be machined from several angles in a single setup using multi-axis machines. This is important because fewer manual workpiece repositionings are required, which reduces the possibility of alignment errors, a crucial factor when machining precision machined valve parts.

- Complicated Features – Only sophisticated CNC technology can provide the simultaneous movement and coordination needed for parts like threaded valve stems, contoured plugs, and intricate internal flow channels.

C. The Role of Technology in Quality Assurance

Beyond the machine itself, a top manufacturer like Global Precision Pvt Ltd is dedicated to CNC excellence –

- Versatility of Material – A key component of the industrial valve market, high-end CNC machining fo

- r valves is capable of handling a wide variety of specialty metals, including alloys that are difficult to machine, resistant to abrasion, and corrosion.

- Metrology and Inspection – To confirm that the custom CNC parts fulfill the extremely tight tolerances outlined in the design, parts are measured using Coordinate Measuring Machines (CMMs) and other cutting-edge metrology tools after they have been machined. The last quality seal is this stringent inspection procedure.

Partnering for Precision – Choosing the Right CNC Manufacturer

The dependability of your entire system depends on the CNC manufacturing services provider you choose. You need to work with a specialist rather than a general job shop when the application is crucial.

A. The Advantage of Global Precision

Reputable companies like Global Precision Pvt Ltd are distinguished by their expertise and steadfast dedication to the high standards of quality required by the valve industry –

- Committed Focus – High-precision components, frequently for the most demanding industries (such as valves, aerospace, and medical), are the exclusive focus of Global Precision Pvt Ltd. Because of their specialized focus, they consistently invest in the specialized tooling, cutting-edge multi-axis CNC lathes and mills, and quality control systems needed for industrial valve components.

- Certification and Compliance – Certification and expertise go hand in hand. Seek out ISO 9001 certification and a history of fulfilling industry-specific requirements. A trustworthy partner guarantees that your custom CNC parts will satisfy the final valve assembly’s regulatory requirements.

- Design for Manufacturability (DFM) – Your engineers will collaborate with a leading CNC manufacturing services provider from the very beginning of the design process. They recommend small design changes that streamline the manufacturing process without compromising performance, frequently saving money and cutting lead times, using their specific expertise in CNC machining for valves.

B. The Long-Term Return on Investment

Although precision machined valve parts cost more up front than inferior substitutes, they provide unmatched long-term cost advantages –

- Decreased Downtime – The risk of valve failure is significantly reduced by flawlessly manufactured parts, which can save millions of dollars in expensive production shutdowns and emergency repairs.

- Extended Service Life – By using the proper materials that are expertly machined, industrial valve components are able to withstand wear and corrosion for a longer period of time. This greatly increases the operational life of the valve and lowers the need for maintenance.

Precision is essential in the field of industrial fluid control. For valves, CNC machining offers the precision, robustness, and personalization required by contemporary industrial applications. Businesses may strengthen their operations and guarantee safety, effectiveness, and a strong supply chain for their vital industrial valve components by emphasizing high-quality custom CNC parts and collaborating with knowledgeable CNC manufacturing services providers like Global Precision Pvt Ltd.