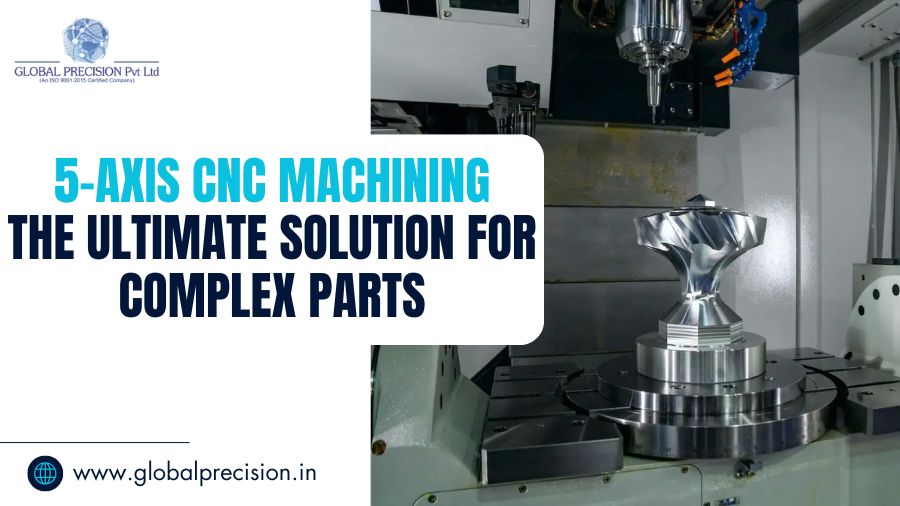

5 Axis CNC Machining is the latest technological advancement in the manufacturing sector, and is a modern method used to make complex parts with intricate details. From aerospace components to medical and automotive parts, this advanced machining method delivers accurate results with higher accuracy.

Unlike regular machines that move in three ways, 5-axis CNC machines can move in five directions while cutting the material, making them highly useful for manufacturing parts with sharp details. This modern manufacturing method not only saves time but also offers exact results even for parts with difficult shapes and angles. Continue reading this blog to learn more about 5 Axis CNC machining, its core parts, benefits, and more.

What is 5 Axis CNC Machining?

A 5-axis CNC machine is a modern tool used to make very detailed and complex parts. While cutting the material, it can move in five different directions, and with this technology, it is easy to reach tricky angles and secure difficult shapes. The X, Y, and Z axes let the machine move the tool in a linear direction, such as up-down, left-right, and forward-backward.

The additional axes, A, B, and C, allow the machine to rotate, spin, and tilt the tool or parts. With the help of 5-Axis CNC machining, you can easily reach all five sides of the part, which ends the need for manual repositioning.

Core Parts Of A 5-Axis CNC Machine:

5-axis CNC machines can easily provide highly accurate solutions, even for complex parts, due to their advanced design. Here are some of the core parts of these machines that play a specific role to ensure smooth operations, consistent cutting performance, and precise movements:

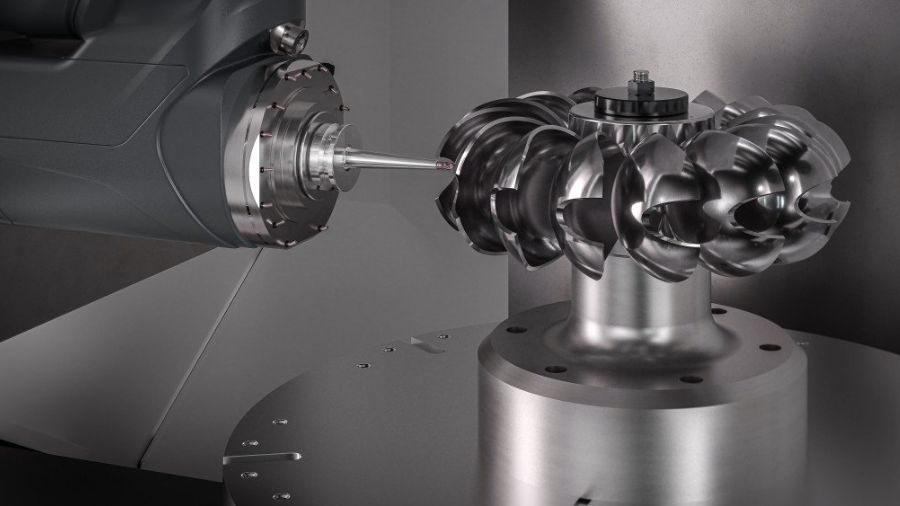

- Spindle- This is the main part of a 5-Axis CNC machine, as it holds and spins the cutting tool at high speed.

- Rotary Table- This component allows the workpiece to rotate on different angles (A & B axes), making it easier to cut complex curves and shapes from multiple sides.

- Linear Guides and Ball Screws- These components help the machine’s movement in straight lines with smooth and steady motion for accurate results.

- Control Panel- This is the most important component of 5 Axis CNC machining, which sends commands to the machine and controls every movement based on the programmed design.

- Tool Changer- This machine can automatically switch tools when needed, so you don’t have to manually set up tools for multiple operations.

- Coolant System- This core component keeps the cutting tool and part cool during the entire process, as overheating can damage tool life and make it difficult to achieve cleaner cuts.

5 Axis CNC Machining: Main Benefits

5 Axis CNC machining offers many advantages over 3-axis machines, as it helps manufacturers save time, improve quality, and handle complex designs with ease.

1. Greater Accuracy and Detailing- With the help of this latest manufacturing technology, manufacturers can work on a part from all directions without manual adjustments. Even for complex aerospace and medical components, these machines offer higher accuracy.

2. Less Time, More Efficiency- 5-Axis CNC machining has ended the need to move or reposition parts and change tools manually, helping manufacturers to save a lot of setup time. Unlike 3-axis machines that need manual setup, these machines can produce complex parts in a single setup, which reduces the risks of manual errors.

3. Superior Surface Finish- 5-axis CNC machines provide continuous and stable movement of the cutting tool. The reduced vibrations during the production process help achieve cleaner and smoother surfaces, eliminating the need for additional finishing work.

5 Axis CNC Machining: Industrial Applications

5-Axis CNC machining is the top choice for various industries, particularly those where accuracy and advanced designs matter the most. Its five axes help manufacturers to work on all sides of a component, making it a trusted choice for businesses across diverse sectors:

1. Aerospace- These machines can easily handle lightweight materials like titanium and aluminum, while maintaining tight tolerances for safety and excellent performance in complex parts like turbine blades and engine parts.

2. Automotive- In this sector, these are used to manufacture engine housings, curved surfaces, and custom interior parts with smooth finishes. These modern manufacturing solutions have helped to fulfill the demand for fast production of high-performance vehicles.

3. Medical- The production of custom implants, surgical tools, and other medical devices, where achieving perfect shapes and smooth edges is necessary, has become easier with 5-axis CNC machines.

4. Energy- Industries like oil and gas, wind, and solar power greatly rely on 5-Axis CNC machining for manufacturing durable and accurate components with complex shapes, like turbine blades and pump housings.

Why Choose 5 Axis CNC Machining For Complex Parts?

When it comes to producing parts and components with complex shapes and detailed designs, no other option can be better than 5 Axis CNC machining, and here are the main reasons why manufacturers across diverse industries are choosing it:

1. Access to Hard-to-Reach Areas- The cutting tool of a 5th-axis CNC machine can tilt and reach tight corners and curved surfaces easily, which was impossible to reach with traditional tools.

2. Less Manual Work- Since this type of CNC machine can move automatically in five directions without manual setup, it saves time and the risk of human errors.

3. Works on a Wide Range of Materials- The best thing about 5 Axis CNC machining is that it can handle a wide range of materials, including aluminum, stainless steel, titanium, and plastic, making it a perfect choice for manufacturers across different industries.

4. Supports Complex CAD Designs- Many parts today are designed using advanced CAD software; these machines can read these files and follow the commands to produce the parts and components with exact details.

Conclusion

5-Axis CNC machining has significantly changed the production process of complex parts with its ability to cut from different angles in a single setup. From saving time to improving accuracy and handling the most detailed designs with ease, this modern manufacturing method offers many benefits to manufacturers.

No other technology can offer better speed, versatility, and minimal error risk than this for industries that demand perfection. Are you looking for a dependable partner for 5-Axis CNC machining support and solutions? End your search with Global Precision Pvt. Ltd., the leader in high precision engineering in India for the last 14 years.

We serve businesses across diverse industries with quality precision components and products. Our team focuses on innovative solutions, speedy but accurate production, and custom-made component manufacturing based on clients’ needs, which makes us a trusted partner for perfect solutions for complex parts.